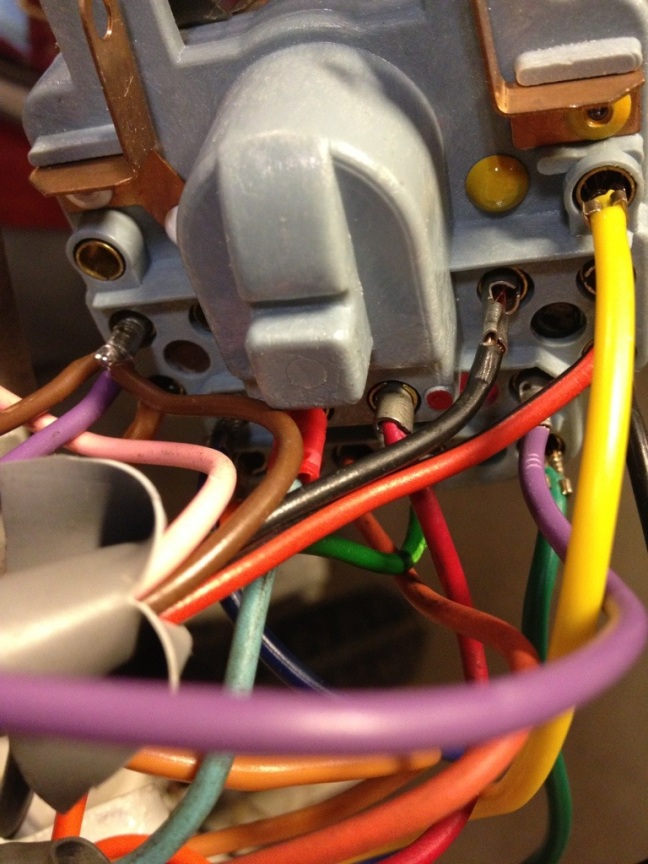

I thought it was time to hook up the spaghetti nightmare that we know as Lambretta electrics.

My loom was custom made and ordered from Beedspeed.

I had it made with the options for running the P200 rear brake light switch, extra cable at the rear for a compressor air horn. An option to have power to extra gadgets as iPhone or satnav. Toolbox kill switch and such. Mainly just a couple of extra wire options if I decide to go that route.

Luckily everything is colour coded so that you easily see what goes where.

Hooked the ignition up, the main loom and the horn/light box cables.

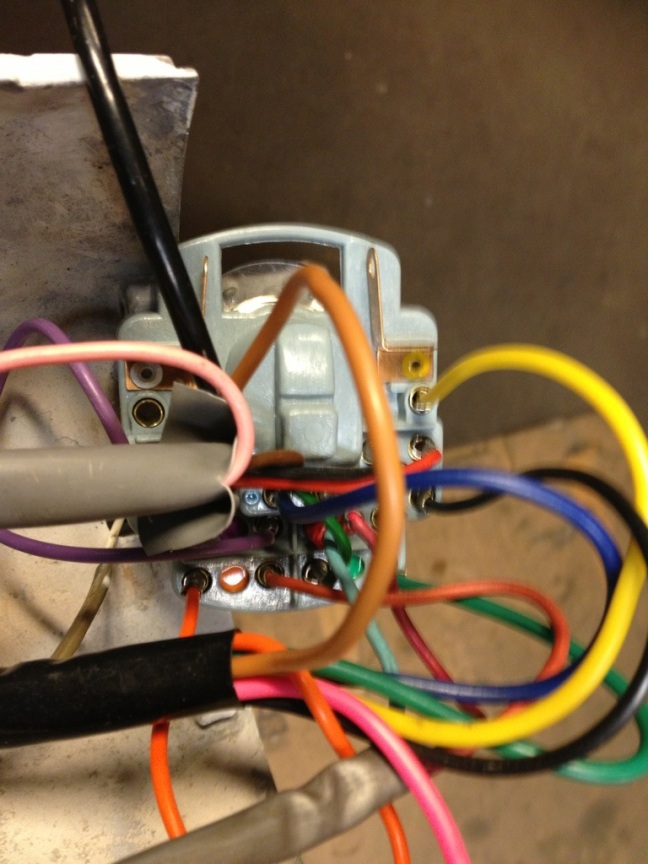

At the rear of the scoot I installed the Jockey Boxenstop brackets for Wassel and cdi unit. Both the cables from the loom and from the Wassel are quite long so I used the frame to wrap them around one time to take up the extra length. The CDI unit, Ducati brand, sitting on the bracket. It is earthed on the bracket between extra washers.

The CDI unit, Ducati brand, sitting on the bracket. It is earthed on the bracket between extra washers.

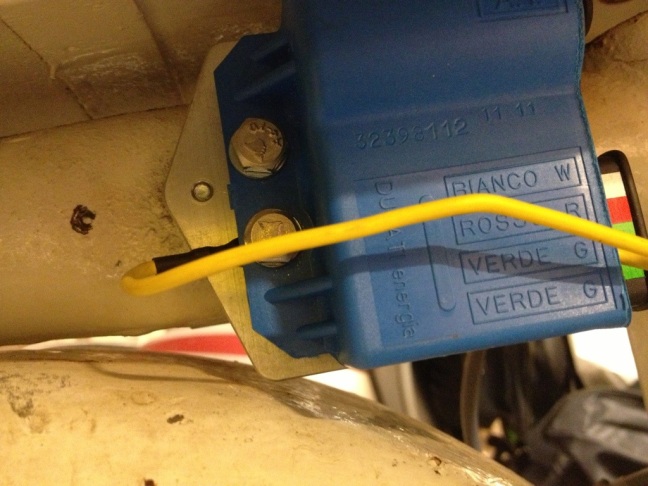

The Wassel. Also earthed on the bracket. The Wassel unit is smaller than the usual rectifier used on the Lambretta so the bracket was drilled for a hole more suited to the size of the Wassel.

The Wassel. Also earthed on the bracket. The Wassel unit is smaller than the usual rectifier used on the Lambretta so the bracket was drilled for a hole more suited to the size of the Wassel.

Now there is an earth supposed to connect to the flywheel cowling. I just don’t have any spare wire to connect there. Makes me wonder.

All the electric parts where purchased from beedspeed. Top service and top quality!