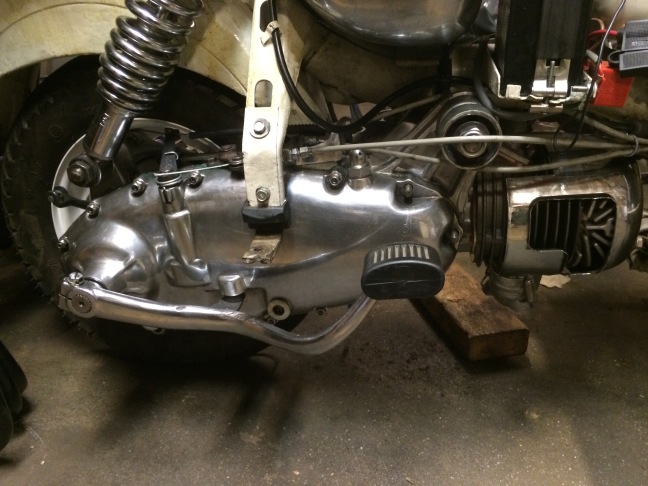

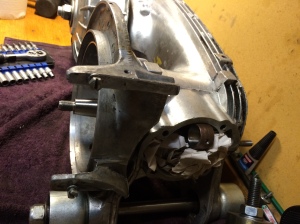

So, I have at last reached the final stage of this engine tuning and rebuild. Everything is assembled and ready to go back into the bike.

It looks good and shiny and matches the chromed Escort rear shock absorber.

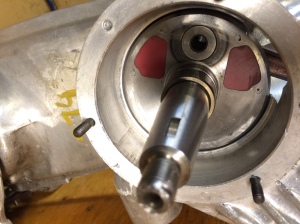

Next up I connected the PHBH 30 carburetor.

Jetting is:

Main 134

Float jet 350

AV268 atomizer

X13 with clip on top notch

40 slide

55 idle jet

Airscrew 1,5 turns out

The timing was set to 17 degrees.

The scooter runs very smoothly, great power and guts. The MBGM exhaust suits it fine giving good spread of power.

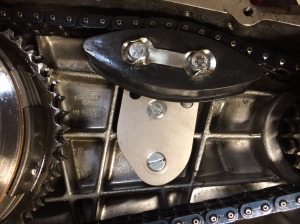

Things I might change in the future is the front sprocket to slightly lower the gearing for more top speed.

I run the SIL chain springs and after 400km they become to weak. Time to upgrade them to the GT springs to cure clutch slip. Unfortunately there’s no dyno around here so I will never know my HP figures and all set up will have to be done on the road.

I did undertake a longer journey of approximately 400km late summer running with passenger and it was a smooth ride. Never ever reached to power since my riding mates didn’t go fast enough for the GT200 kit! Only half throttle cruising and mostly on third gear.

I really recommend the kit to anyone looking for a upgrade!

So that’s it for now then. Keep reading and do post a question or two.